Food Grade Bulk Bags

Our food and pharmaceutical grade FIBCs are manufactured in certified clean rooms that adhere to the highest quality standards.

REQUEST A QUOTE

FIBCs You Can Trust

Food-grade FIBCs are commonly used across food processing and agricultural industries for handling dry, flowable products such as flour, sugar, salt, breadings, starch, beans, wheat, corn, malt, and rice. These materials often require strict contamination control and consistent quality standards throughout storage and transportation.

Hygiene & Quality Control Standards

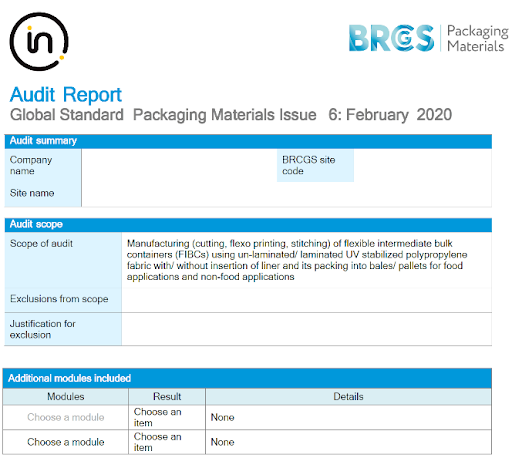

Whether you’re buying cereal or soda, packaging comes into direct contact with the food products you buy. Therefore, the manufacturing practices of the suppliers that produce these items are critical to your health and safety. Our food and pharmaceutical grade bags are produced in BRCGS and AIB certified clean rooms that adhere to the highest quality and hygiene standards.

Standards which are present in our manufacturers’ BRCGS and AIB certified facilities:

- 100% Virgin Raw Materials

- Proper Ventilation

- Pest Control Procedures

- Metal Detection

- Ultrasonic Cutting

- Light Table Inspection

- Vacuum / Air Cleaning

- Proper Personnel Wardrobe

- Proper Personnel Hygiene

- HACCP (Hazard Analysis and Critical Control Points) Program

- Record Keeping

.jpg)

GFSI Safety Schemes

In accordance with the with the third-party safety schemes that have been recognized by the Global Food Safety Initiative (GFSI), our manufacturing partners have implemented the following programs and safety plans:

- Allergen Management

- Supplier Approval

- Pest Management

- Complaint Management

- Traceability

- Training

- Mock Product Recalls

- Calibration

- Carrier Inspection

- Foreign Material Control

- Sanitation

- Food Defense

- Supplier Corrective Action

Third-Party Certifications

Food grade FIBCs should only be manufactured by certificated suppliers that meet the standards established by GFSI recognized schemes. Southern Packaging, LP performs extensive due diligence on our food grade quality manufacturing partners to ensure our customers receive the highest quality, most reliable food grade packaging.

Third-party certifications carried by our manufacturing partners include:

- Food Safety System Certification 22000 (FSSC)

- BRCGS – British Retail Consortium: BRC Global Standard for Packaging & Packaging Materials Issue 4

- International Featured Standards (IFS): IFS PAC secure, Version 1

- SQF – Safe Quality Food Institute: SQF Code 7th Edition; Level 2

- ISO 9001:2015

- ISO 14000: 2015

- OHSAS 18001:2007

.jpg)

Storage Considerations

Food products packaged in FIBCs are typically stored indoors in controlled environments. Shelf life can be an important consideration depending on the product being stored. While there is no strict expiration date for food-grade bulk bags, a general recommendation is an 18-month usage window under proper storage conditions.

Maintaining clean, dry storage areas helps preserve both the integrity of the packaging and the quality of the food product inside.

Freight & Damage Prevention

While loading efficiency is not typically a concern for food-grade FIBCs, protecting the product during transit is critical. Proper use of dunnage is recommended to help prevent shifting and minimize the risk of damage during transportation.

Maintaining product integrity throughout domestic and ocean freight is essential for food manufacturers who must meet strict quality and safety standards.

Handling & Filling

Food-grade bulk bags can be integrated into manual or automated filling operations depending on the facility setup. For manufacturers using bulk filling systems, equipment providers such as Form-Pak offer solutions compatible with FIBC filling applications.

Ensuring compatibility between filling equipment and bag design helps maintain efficiency while protecting product quality.

Liners, Static & Product Protection

Most food-grade bulk bags are Type B and offer static dissipative properties suitable for typical food applications. Anti-static and UN-certified designs are generally not required for food products.

For moisture-sensitive materials, liners may be used to provide additional protection. However, many food-grade FIBCs are coated and do not require an internal liner. Selecting the appropriate configuration depends on the sensitivity of the product being packaged.

.png)

Why Manufacturers Choose Food-Grade FIBCs

Manufacturers select food-grade FIBCs to ensure clean, contamination-free packaging for their products. Strict manufacturing standards help eliminate risks such as loose tapes, threads, or oil stains that could compromise product safety.

Clean-room production environments and rigorous quality control procedures provide confidence that packaging meets food safety expectations and regulatory standards.

Need food or pharmaceutical-grade bulk bags?

Southern Packaging, LP stocks the largest inventory of on-demand FIBCs in the country. Nearly 1 million FIBCs across 100 SKUs are available for immediate shipment to your plant location. We offer stock and custom-designed food grade FIBCs for any industrial application. Please contact our experienced team of packaging professionals for more information.

100,000 bags shipped in 2025!

Frequently Asked Questions

What is a food grade bulk bag?

A food grade bulk bag is a type of FIBC manufactured to strict hygiene and safety standards to ensure it is safe for direct contact with food products like flour, sugar, or rice. These bags are produced in certified clean rooms using 100% virgin materials.

Are your food grade FIBCs certified?

Yes. Our food grade FIBCs are produced by manufacturers certified under BRCGS, AIB, and other GFSI-recognized safety schemes. Certifications may include FSSC 22000, SQF, ISO 9001, and IFS PACsecure.

What are the hygiene standards for food grade bulk bags?

Our bags are produced in clean rooms with strict protocols including metal detection, pest control, ultrasonic cutting, vacuum/air cleaning, and HACCP programs. Personnel follow stringent hygiene and sanitation procedures to prevent contamination.

Can food grade FIBCs be used for pharmaceutical applications?

Yes. Our food-grade FIBCs meet the high hygiene standards required for both food and pharmaceutical applications. They are suitable for packaging sensitive powders such as whey protein and other pharma-grade materials.

What materials are used in food grade FIBCs?

Only 100% virgin polypropylene and polyethylene materials are used. These ensure the bags are free from recycled content or contaminants that could compromise product safety or regulatory compliance.

What types of food products are commonly packaged in food-grade FIBCs?

Food-grade bulk bags are commonly used for flour, sugar, salt, breadings, starch, beans, wheat, corn, malt, rice, and other dry, flowable food ingredients.

What food products are commonly packaged in food-grade bulk bags?

Food-grade FIBCs are commonly used for dry, flowable ingredients such as flour, sugar, salt, breadings, starch, beans, wheat, corn, malt, and rice.

Are liners required for food-grade bulk bags?

Liners may be used for moisture-sensitive products. However, many food-grade FIBCs are coated and do not require an internal liner. The best option depends on the product being packaged.

Do food-grade bulk bags require anti-static designs?

Most food-grade bulk bags are Type B and have static dissipative properties suitable for typical food applications. Anti-static designs are generally not required for food products.

How should food-grade bulk bags be stored?

Food products packaged in FIBCs are typically stored indoors in controlled environments. While there is no strict expiration date, a general recommendation is an 18-month usage window under proper storage conditions.

How do you reduce the risk of damage during shipping?

Damage prevention is a key focus during transportation. Proper use of dunnage is recommended to help prevent shifting and reduce the risk of damage during transit.

Get In Touch

Our team can deliver the packaging you need, when you need it. Complete your info here and we'll be in touch quickly.

-1.png?width=160&height=160&name=Rectangle%2010%20(1)-1.png)

.png?width=160&height=160&name=Rectangle%2014%20(1).png)