FIBC Liners

We offer a full suite of FIBC liner solutions for liquid and dry products. Our custom form fit and flat tube liners are manufactured using various film types including EVOH, Foil, HDPE, LDPE, and PP. Liner thicknesses range from 1.0 – 8.0 mil.

Liner Functionalities

- Eliminates dusting and leakage

- Oxygen and Moisture Barrier

- Puncture Resistant Barrier

- Food Contact Approved

- Conductive / Anti- Static

Liner Attachment Types

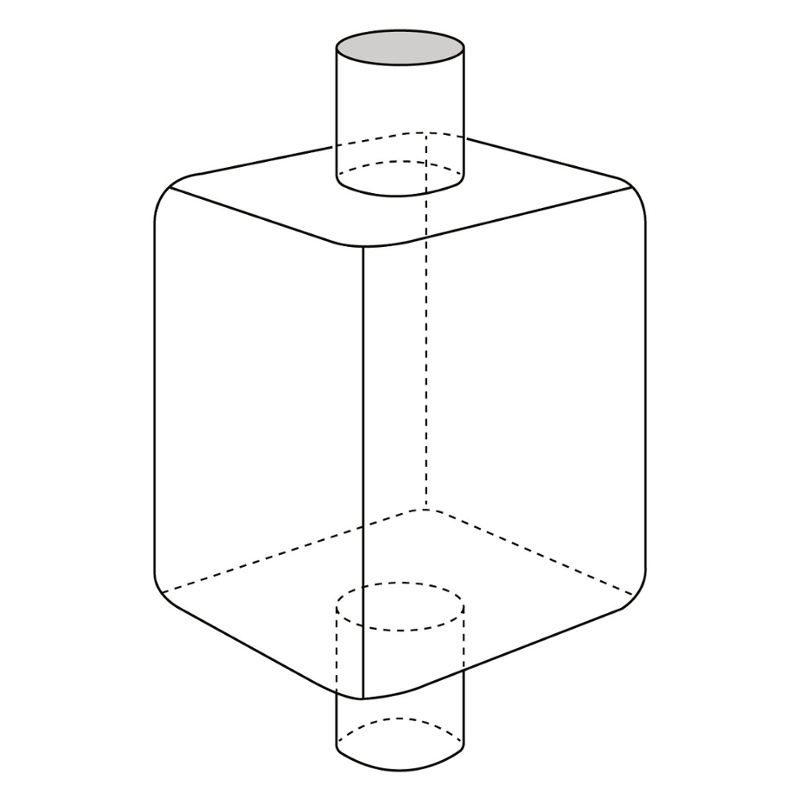

Liners can be factory inserted into your FIBC or purchased separately. They can be loosely inserted, attached at 8 points using tabs, or glued into the body of the bag. In addition, the liner openings can be cuffed and sewn to the filling and discharge spouts of your bag.

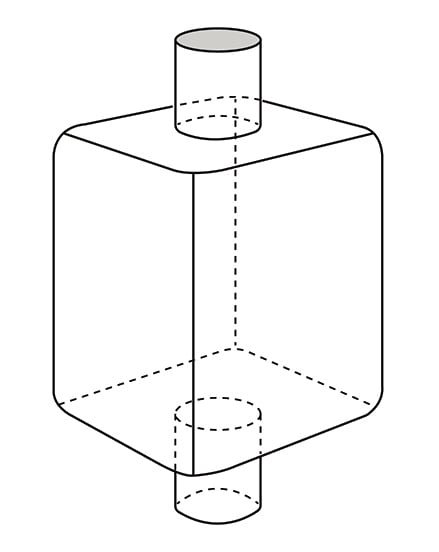

Loosely Inserted / No Attachment

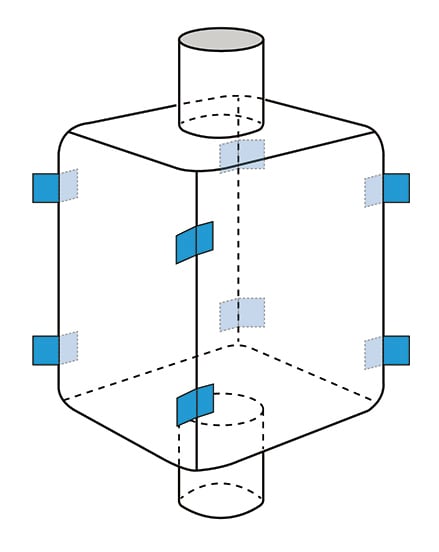

Tabbed In / Sewn In

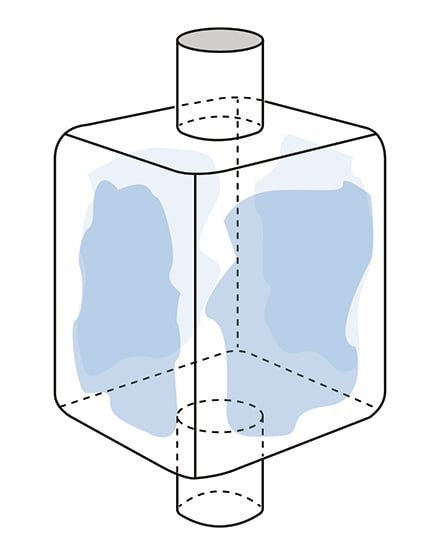

Glued In

Liner Constructions

FIBC liners are available in 3 basic constructions: Form Fit, Lay Flat, and Baffled. Each construction provides enhanced protection against leakage, contamination, and moisture intrusion.

Form Fit Liner

Form fit liners take the exact form of the body of the FIBC including the filling and discharge spouts. This ensures efficient filling and discharging of the FIBC. In addition, liner filling and discharge spouts can be tailor-made to the exact size specifications of the customer.

Technical Applications & Features

- Eliminates dusting and leakage

- Eliminates wasted space

- Reduces tearing and twisting

- Improves stacking and stability of the bag

- Improves compatibility with filling equipment

- Promotes fast filling and discharging

- Packed on rolls or individually cut

- Clear or custom colors

- Can be removed and reused

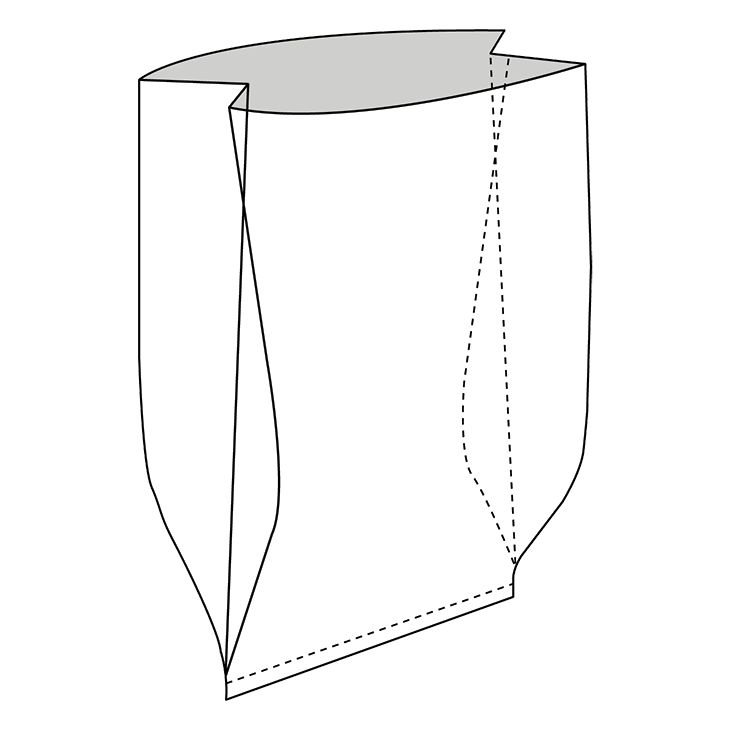

Lay Flat Liner

A lay flat tube is a common, cost-effective style of FIBC liner. The liner has no spouts or contours. Generally, the liner is open on one end and heat sealed on the other. Lay flat liners can be inserted and attached into a bulk bag in the same manner as a form fit liner.

Prior to filling the bag, it is recommended that the liner is pre-filled with air to remove possible twists or wrinkles in the liner.

Technical Applications & Features

- Eliminates dusting and leakage

- Cost effective vs. form fit style liner

- Gusseted

- Clear or custom colors

- Improves compatibility with filling equipment

- Packed on perforated rolls

- Sealed or open bottom

- High Strength

- Can be removed and reused

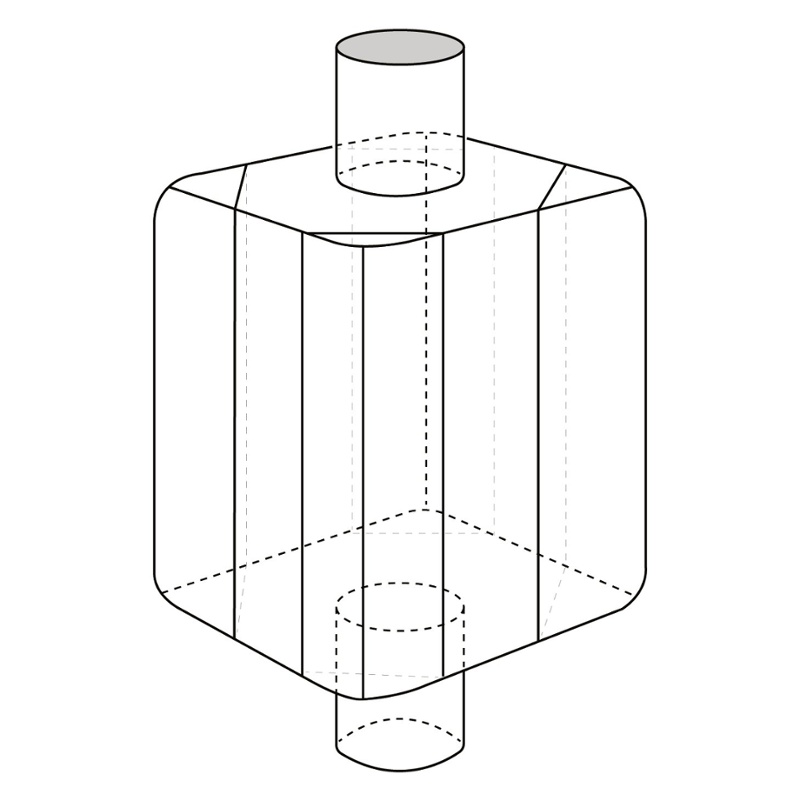

Baffled Liner

Oftentimes a standard baffled FIBC is insufficient for ultra-clean applications. When the functionality of a baffled bag and film liner is required, a baffled liner is appropriate.

Baffled liners allow a standard bulk bag to maintain a square shape. The liner is form fitted to the bag and utilizes internal baffles to prevent bulging that could result in a rounded footprint. The square shape promotes greater bag stability and stackability. Furthermore, the square shape greatly improves storage capacity.

Technical Applications & Features

- Eliminates dusting and leakage

- Increased FIBC stackability

- Increased stability

- Can hold up to 30% more product in a given space

- Custom formed spouts for efficient filling and discharge

Specialty Liners

Aluminum Foil, Anti-Static, Conductive, and Food Grade liners offer superior protection for highly sensitive products. We offer these unique custom liner solutions for customers requiring the highest degree of product security.

Aluminum Foil Liners

Foil liners, made of aluminum-laminated films, offer superior protection against oxygen, moisture, and UV light. In addition, they greatly reduce or eliminate product odor. Foil liners are form fit to the FIBC enhancing filling, discharging, and handling of the bag.

Technical Applications & Features

- Forms impermeable watertight barrier

- Ultimate moisture & gas protection

- Available with custom filling and discharge spouts

- Custom film formulations

- Ideal for moisture sensitive dry ingredients

Anti-Static / Conductive Liners

Anti-Static and conductive liners are specially formulated with film additives that dissipate static charges away from potentially flammable products and environments. In addition, they can eliminate dry chemical static cling.

Technical Applications & Features

- Manufactured with migratory or permanent anti-static film

- 12 month shelf life for migratory anti-static film

- 5 year shelf life for permanent anti-static film

- Manufactured in accordance with IEC 61340-4-4 Ed2 regulation

- EU 10/2011 Compliant

| Liner Type | Anti-Stat Properties | Surface Resistivity | FIBC Type |

|---|---|---|---|

| L1 | Conductive | ≤ 107 Ω | C |

| L2 | Anti-Static | 109 Ω to 1012 Ω | B, C & D |

| L3 | Resistive with low breakdown voltage (<4kV) | greater than 1012 Ω | B |

Food / Pharma Grade Liners

Polyethylene and polypropylene are approved by the FDA for food contact. Our food and pharmaceutical grade liners are produced in BRCGS and AIB certified clean rooms that adhere to the highest quality and hygiene standards.

Standards which are present in our manufacturers’ BRCGS and AIB certified clean rooms:

Technical Applications & Features

- 100% Virgin Raw Materials

- Proper Ventilation

- Pest Control Procedures

- Metal Detection

- Ultrasonic Cutting

- Light Table Inspection

- Vacuum / Air Cleaning

- Proper Personnel Wardrobe

- Proper Personnel Hygiene

- HACCP (Hazard Analysis and Critical Control Points) Program

- Record Keeping

Frequently Asked Questions

What is an FIBC liner?

An FIBC liner is a protective inner layer placed inside a bulk bag to prevent contamination, leakage, and moisture intrusion. Liners are commonly used for sensitive or fine dry products and liquids.

What types of FIBC liners are available?

Southern Packaging offers form fit, lay flat, and baffled liners. Each is engineered for different applications—form fit liners match the bag shape, lay flat liners are cost-effective tubes, and baffled liners provide enhanced stackability and stability.

Are your FIBC liners food-grade approved?

Yes. Our polyethylene and polypropylene liners are FDA GRAS approved for food contact. Food-grade and pharma-grade liners are manufactured in BRCGS and AIB-certified clean rooms for maximum hygiene.

Can liners be attached to FIBCs?

Yes. Liners can be loosely inserted or secured using sewn-in tabs, glue, or sewn cuffed spouts. Attachment type depends on your application, fill method, and discharge needs.

What are anti-static or conductive FIBC liners used for?

These liners are used to safely package flammable powders or materials prone to static build-up. They help dissipate static electricity and comply with Type B, C, or D FIBC requirements.

100,000 bags shipped in 2025!

Get In Touch

Our team can deliver the packaging you need, when you need it. Complete your info here and we'll be in touch quickly.