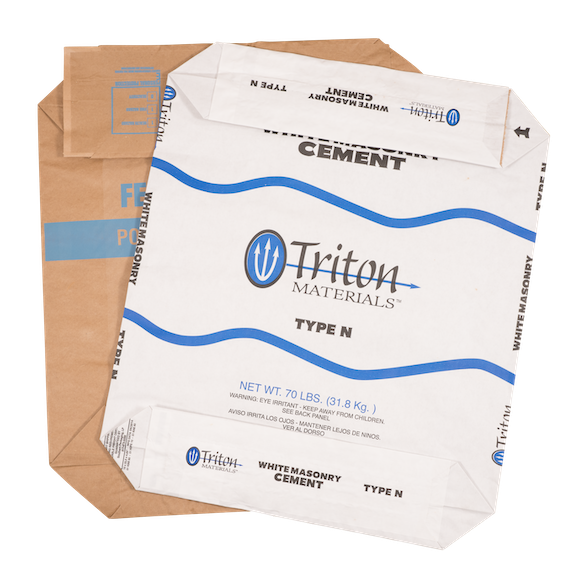

Multi-Wall Paper Valve Bags

Our multi-wall paper valve bags are a proven packaging solution for manufacturers handling dry flowable products that require clean, efficient, and high-speed filling.

Built using sustainably sourced paper plies and optional barrier films, each valve sack is engineered for durability, consistent performance, and reliable palletization in demanding industrial environments.

Through precise construction and rigorous quality control, our valve bags support efficient filling processes while delivering long-term value across production, storage, and transportation.

.png?width=1200&length=1200&name=A7405006%20copy%20(1).png)

Built for Speed, Accuracy, and Durability

A Pasted Valve Stepped End (PVSE) multi-wall paper bag is one of the most widely used valve sack styles in industrial packaging.

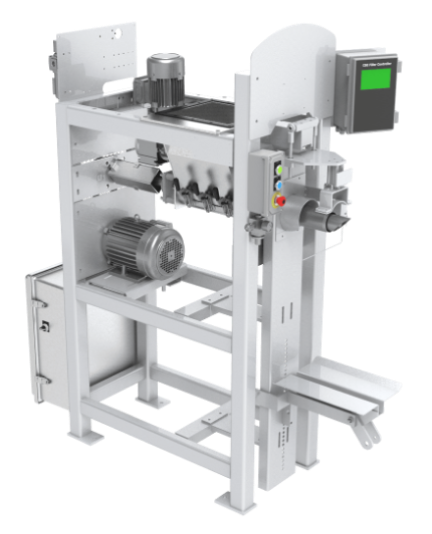

Designed for automated, high-speed filling equipment, product enters the bag through a horizontal filling spout using air, impeller, or auger systems.

Once the bag is released from the filling sprout, internal product pressure causes the valve opening to self-seal—eliminating the need for additional closing steps and improving line efficiency.

This construction creates a clean, squared-up package that:

- Palletizes securely

- Maintains consistent shape

- Allows printing on side or end panels for easy identification in pallet loads

Features & Benefits of Bags with Valves

- Ideal for packaging building materials, chemicals, minerals and agriculture

- Designed for high speed filling

- 20-100lb Capacity

- Manufactured with 1-6 plies of paper

- Multiple valve configurations for unique filling requirements

- Multiple moisture barrier options

- Flexographic printing in up to ten colors

- Perforated paper for fast air evacuation

Valve Types

Valve bags are filled through an opening located in the top corner of the bag. Product is pumped or forced into the bag via air pressure, impeller, or auger. When the bag is expelled from the filling equipment, the internal forces exerted by the contents prompt the opening of the valve bag to self-seal. This self-sealing design enables secure containment and streamlined handling from fill to final delivery.

Bags with valves can be equipped with different valve or “sleeve“ types. Each sleeve type performs the same basic function. However, the proper sleeve type for your product and packing equipment needs to be evaluated when designing a valve bag. Our valve type capabilities include:

- Double Trap

- Reinforcing Strip

- Paper Tube Insert

- Reinforced Poly Lock

- Tuck-In

- Hinged Tuck-In

- Sonic/Heat Seal

- Double Trap Sonic Seal

- Reduced Sleeve

Poly Lock

.png?width=601&height=400&name=SP_Sonic%20Seal%20(1).png)

Sonic Seal

Tuck In

How to Save Money with 2-PLY Extensible Paper Bags

Modern sack kraft paper is now so strong that 3-ply bags are seldom necessary - resulting in significantly reduced paper bag costs. Read our recent blog to learn how 2-ply bags can save you more money!

Paper Types

| Traditional Kraft Paper | High Performance Extensible Paper |

|---|---|

| Manufactured from short wood fiber | Manufactured from long wood fiber |

| Heavy, coarse sheet | Smooth sheet |

| Strength through high basis weight | Strength through superior energy absorption |

| Limited stretch | 6-7% stretch |

| Low levels of porosity | High levels of porosity |

| Limited energy absorption | Superior energy absorption |

| Ideal for 3-4 ply bag construction | Ideal for 2 ply bag construction |

Download our UN Paper Bag Brochure

Download our brochure on UN-certified paper bags that includes

ideal uses, bag features, and more!

.webp)

Custom Multi-Wall Paper Packaging Solutions

Every filling line and product behaves differently. We offer fully customized valve bag packaging solutions engineered around your material characteristics, filling equipment, and logistics requirements.

Available bag styles include:

- PVSE

- SOM

- PBOM

- Webb PBOM

- SOS

- UN Certified

- AIB

Minimum order quantities and artwork charges may apply. Lead times typically range from 4–16 weeks depending on bag construction and printing requirements.

Frequently Asked Questions

What is a pasted valve stepped end (PVSE) bag?

A PVSE bag is a multi-wall paper valve bag with a stepped end design used for packaging dry flowable products. It features a valve for high-speed filling and self-seals when discharged from the filling machine, offering secure containment and stackable square dimensions.

What products are commonly packaged in valve bags?

Valve bags are ideal for building materials, chemicals, minerals, and agricultural products. Their construction supports efficient high-speed filling and safe handling of dry flowable goods like cement, fertilizer, and industrial powders.

What valve types are available for multi-wall paper bags?

Southern Packaging offers several valve types including poly lock, sonic seal, tuck-in, double trap, and reinforcing strip options. The right valve depends on your product and filling method (air, impeller, auger, etc.).

Can your multi-wall valve bags be customized?

Yes. Southern Packaging provides fully customized valve bags with options for size, number of paper plies, moisture barriers, and up to ten-color flexographic printing. Custom designs can be tailored to your equipment and application needs.

On-Demand Packaging Solutions

For customers needing bags immediately, we maintain a substantial inventory of off-the-shelf printed and plain bags. Contact us today to learn more about our in-stock PVSE bags.

-1.png?width=160&height=160&name=Rectangle%2010%20(1)-1.png)

.png?width=160&height=160&name=Rectangle%2014%20(1).png)