The FIBC Manufacturing Process

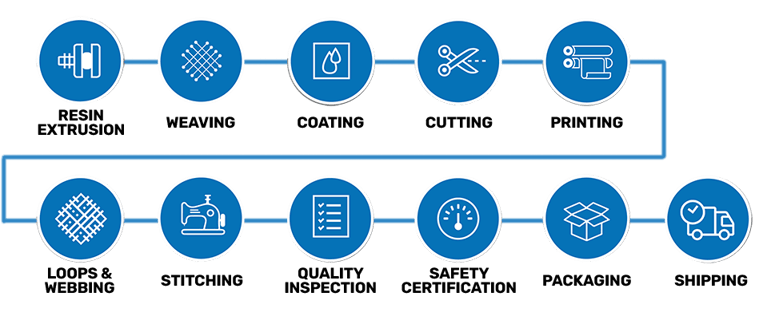

Flexible Intermediate Bulk Container (FIBC) manufacturing requires meticulous attention to detail at every stage. Bulk Bags must be designed and assembled with precision to ensure they meet both functional and safety requirements. Producing FIBCs is a labor-intensive process that involves not only specialized machinery but also skilled craftsmanship and strict quality control. This complex process demands a high degree of skill and experience, as even small imperfections can compromise the performance of the finished product. The bulk bag manufacturing process can be broken down into 12 essential steps, each one playing a critical role in achieving a final product that meets rigorous industry standards for durability and safety. From the extrusion of polypropylene yarn to weaving, cutting, printing, and final inspection, no step is less important than another. The seamless coordination between each phase ensures that the FIBC bags perform reliably in demanding industrial environments.

WHAT WE DO

Raw Material Sourcing

We carefully select high-quality virgin polypropylene resin to ensure the durability and safety of our FIBC bulk bags.

Extrustion

Virgin polypropylene resin is melted and extruded into sheets. From there the sheets are cut into heavy tapes and wound onto bobbins.

Weaving

The thick tapes are woven into a durable fabric, which forms the main body of the FIBC bags.

Coating

The fabric can be laminated with a thin layer of polypropylene film for fine, dusty products.

Cutting

The fabric is precisely cut into the required sizes and shapes for different bag specifications.

Printing

Custom printing options are available for branding the FIBC bags with logos and product information.

Loops & Webbing

Various features such as lifting loops, discharge spouts, and liners are added according to customer requirements.

Stitching

The cut pieces are sewn together using advanced techniques to ensure strength and reliability.

Quality Inspection

Each bag undergoes rigorous testing to ensure it meets our high standards of quality and safety.

Safety Certification

Final touches are added, and the bags are prepared for shipment.

Packaging

The finished FIBC bags are carefully packaged to prevent damage during transit.

Shipping

The bags are shipped to our customers around the world, showcasing our capabilities as a FIBC jumbo bag manufacturing company.

Bulk Bag Lead Times

The majority of all FIBC bags utilized in the United States are imported from other countries. India and China manufacture over 70% of the bulk bags imported into the U.S. each year.

In general, bulk container bags that are manufactured in other countries and imported into the country are substantially less expensive than domestically produced bags. However, manufacturing lead time, or the time it takes from the moment an order is placed to the time it delivers, can be substantial.

.png)

Lead times on bulk bags vary based on a number of different factors. These factors include:

- Country of Manufacture:

Different countries have varying production and shipping time - Raw Materials: Availability and quality of raw materials can affect production speed.

- Bag Type: Custom or specialized bags may take longer to produce.

- Plant Capacity: The manufacturing plant’s capacity and efficiency play a significant role.

- Ocean Transit Type: The shipping method and route can impact delivery times.

- U.S. Customs: Clearance processes can add to lead times.

- Rail Transit Time: Rail transport within the U.S. can also be a factor.

- Over-the-road Transit Time: Final delivery to the customer’s location via truck.

MANUFACTURINGWhy Choose Southern Packaging ?

Southern Packaging partners with top FIBC bulk bag manufacturers, ensuring high-quality products through several key factors:

- High-Quality Products:We use premium materials and advanced manufacturing processes to ensure our bulk bags are durable and reliable.

- Customization Options:Our team can create custom FIBC bags tailored to your specific needs, including size, printing, and additional features.

- Experienced Team:Our skilled professionals have years of experience in the FIBC industry, ensuring you receive premium products and responsive service.

- Competitive Pricing:We offer competitive prices without compromising on quality, providing great value for our customers.

- Global Reach:With a strong logistics network, we can ship our products efficiently to customers worldwide.

%20(1).jpg)

MANUFACTURINGDiverse Applications of FIBC Bags

Our FIBC bags are versatile and suitable for various industries, including:

- Agriculture:Ideal for grains, seeds, and fertilizers, ensuring protection and integrity.

- Construction:Perfect for transporting heavy materials like sand, gravel, and cement.

- Chemicals and Pharmaceuticals:Safe for hazardous materials and chemical powders with UN-certified options.

- Food Processing:Suitable for food ingredients and animal feed, meeting stringent hygiene standards.

Contact Us for Your FIBC Bag Needs

Contact Southern Packaging today to learn more about the FIBC bag manufacturing process through our network of trusted manufacturers, or to request a quote. Our team of experts is here to guide you in finding the ideal bulk bag solution for your specific requirements, ensuring you have access to the best products crafted by industry-leading manufacturers.

Frequently Asked Questions

What factors affect the lead time for FIBC bags?

Lead times depend on the country of manufacture, raw material availability, bag type, plant capacity, ocean transit, customs clearance, and domestic transit methods.

How long does it take to receive FIBC bags after placing an order?

Lead times vary based on customization, manufacturing location, and shipping logistics. Contact us for specific timelines.

Can FIBC bags be customized for specific needs?

Yes, we offer customization options for size, printing, lifting loops, discharge spouts, liners, and other features.

Are your FIBC bags suitable for hazardous materials?

Yes, we provide UN-certified FIBC bags designed for safe handling of hazardous and chemical materials.

Do you provide bulk discounts?

Contact us to discuss bulk order pricing and potential discounts.

Get In Touch

Our team can deliver the packaging you need, when you need it. Complete your info here and we'll be in touch quickly.

-1.png?width=160&height=160&name=Rectangle%2010%20(1)-1.png)

.png?width=160&height=160&name=Rectangle%2014%20(1).png)