How AI and Automation Are Revolutionizing the Global Paper Valve Bags Market

Thanks to an increasing integration of artificial intelligence (AI) and automation, the packaging industry is undergoing a transformation like never..

October 5, 2020

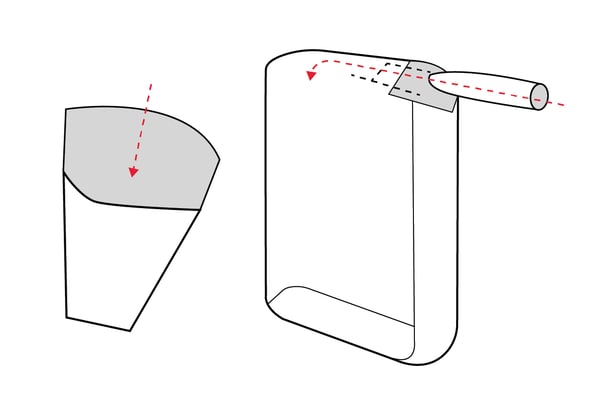

A Pasted Valve Stepped End (“PVSE”) bag is a common industrial packaging style designed to package a wide variety of dry flowable products. Valve bags are packed on equipment that deposits material into the bag via a horizontal filling spout. Valve packing equipment can range from manual, hand-spouted equipment to modern fully-automated equipment.

Valve bags are packed on equipment that deposits material into the bag via a horizontal filling spout. Valve packing equipment can range from manual, hand-spouted equipment to modern fully-automated equipment.

Valve bags are filled through an opening located in the top corner of the bag. The product is then pumped or forced into the bag via air pressure, impeller, or auger. Properly sizing the bag is critical to achieving your operational objectives.

The following tables are useful in sizing valve bags:

Table I shows recommended valve sizes for specified filling tube outside diameters (O.D.) without inflatable sealers.

Table II shows the same information for filling tubes with sealers.

|

Filling Tube O.D. |

Nominal Valve Size |

Filling Tube Circumference |

|

1.625 |

3.25 |

5.105 |

|

1.875 |

3.75 |

5.890 |

|

2.125 |

4.00 |

6.675 |

|

2.250 |

4.25 |

7.068 |

|

2.375 |

4.50 |

7.461 |

|

2.500 |

4.75 |

7.854 |

|

2.750 |

5.00 |

8.639 |

|

3.000 |

5.50 |

9.424 |

|

3.250 |

5.75 |

10.210 |

|

3.500 |

6.25 |

10.995 |

|

Filling Tube O.D. |

Nominal Valve Size |

Filling Tube Circumference |

|

1.625 |

3.75 |

6.105 |

|

1.875 |

4.25 |

6.890 |

|

2.125 |

4.50 |

7.675 |

|

2.250 |

4.75 |

8.068 |

|

2.375 |

5.00 |

8.461 |

|

2.500 |

5.25 |

8.854 |

|

2.750 |

5.50 |

9.639 |

|

3.000 |

6.00 |

10.424 |

|

3.250 |

6.25 |

11.210 |

|

3.500 |

6.75 |

11.995 |

Southern Packaging offers a wide variety of bag styles to suit all of your multi-wall paper and poly packaging needs. Our package design specialists will help you properly size and develop a custom solution for your product.