Bagging Equipment for Optimal Packaging Efficiency

Discover the power of modern bagging equipment

Optimize your packaging process and streamline your production line with the latest advancements in bagging technology. Quickly and efficiently, fill, seal, and palletize a broad range of powders, flakes, and granular products. Southern Packaging LP is a proven industrial bag supplier that supports a diverse range of heavy manufacturers. Leverage our decades of experience when evaluating your next bagging project.

We proudly support Choice Bagging Equipment and their portfolio of innovative bagging solutions. CBE, located in Taylor, Texas, provides durable, user-friendly bagging and palletizing systems to clients worldwide.

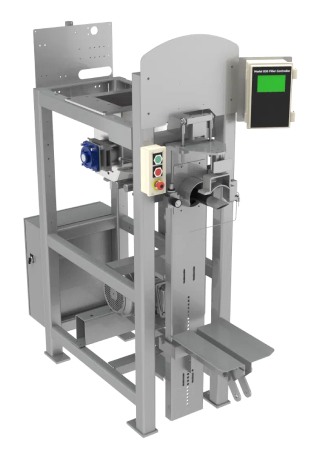

Types of Bag Filling Equipment

Valve Bag Fillers

A Pasted Valve Stepped End ("PVSE") bag is a common industrial packaging style designed to package dry flowable products. Valve bags are packed on equipment that deposits material into the bag via a horizontal filling spout. When the bag is discharged from the bagging equipment, forces generated by the product inside the bag allow the valve opening to self-seal. Valve openings can also be hermetically sealed using ultrasonic vibration or heat.

Fast, accurate, and efficient, valve bag fillers pump product into bags using gravity, air pressure, impeller, or auger. The enclosed filling process significantly reduces or eliminates spillage and dust hazards. The size, speed, output, and degree of automation of bagging machines vary. There are three basic types of valve bag filling machines: auger, forced air, and impeller.

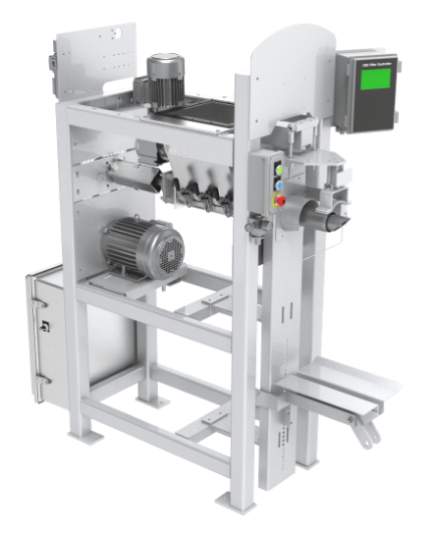

Auger Valve Bag Filler

Auger packers utilize a horizontal screw to convey product from a supply hopper through the fill spout and into the bag. The screw is powered by a drive shaft that turns the screw. This bagging system is ideal for cake-like powders, flakes, and granular products. In general, auger bag filling equipment packs bags slower than impeller or forced air packing equipment.

Bag filling weight range: 20-55 lbs. (9-25 kg)

Production rate: 1-5 bags per minute (material and bag size dependent)

Material density range: 20-75 lbs (9-34 kg) per cubic foot

Operating modes: Semi- (operator assisted) or fully-automatic

Bag types: Internal sleeve and/or tuck-in sleeve paper, plastic film, and poly woven bags

Clean Duty — Model 2050

Industrial Duty — Model 2300

Sonic Seal — Model 2450

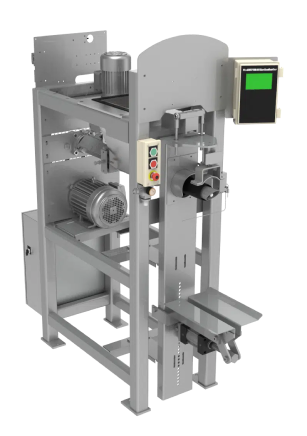

Forced Air Valve Bag Filler

Sometimes called forced flow or pneumatic packers, forced air packers are high-speed, gross-weight baggers. This type fills valve bags by blowing fluidized material into them. The forced air packer offers both excellent weight accuracy and simple operation. Air packers provide high filling rates and minimal strain on bags

Bag filling weight range: 20-110 lbs. (9-50 kg)

Production rate: 1-10 bags per minute (material and bag size dependent)

Material density range: 30-150 lbs (13.6-68 kg) per cubic foot

Operating modes: Semi- (operator assisted) or fully-automatic

Bag types: Internal sleeve and/or tuck-in sleeve paper, plastic film, and poly woven bags

Abrasive-Duty — Model 7200

Digital — Model 7300

Mechanical — Model 7700

Sonic Seal — Model 7550

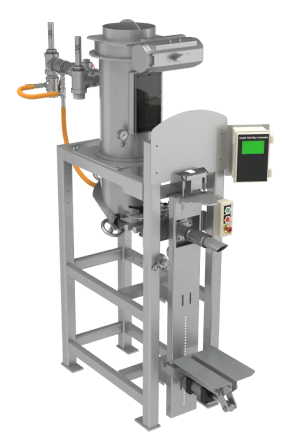

Impeller Valve Bag Filler

Impeller packers use a multi-blade vertical or horizontal impeller to convey product into a bag. Product flows by gravity from the supply hopper into the product feed inlet at the top of the bagging machine. When a fill cycle is initiated, the impeller creates a positive draw on the product, moving it through the feeder and into the bag. The impeller packer is designed for maximum efficiency by entraining less air, which results in faster filling rates and smaller-sized bags.

Bag filling weight range: 20-110 lbs. (9-50 kg)

Production rate: 1-8 bags per minute (material and bag size dependent)

Material density range: 50-100 lbs (22.7-45.45 kg) per cubic foot

Operating modes: Semi- (operator assisted) or fully-automatic

Bag types: Internal sleeve and/or tuck-in sleeve paper, plastic film, and poly woven bags

Digital Vertical — Model 8300

Digital Horizontal — Model 9300

Mechanical Vertical — Model 8400

Need Bulk Bags On Demand?

With the largest inventory of on-demand bulk packaging products in the country, you get your bags faster. To explore our bulk bag types, options, and services, download our free product brochure.

Get In Touch

Our team can deliver the packaging you need, when you need it. Complete your info here and we'll be in touch quickly.