Poly Bag Solutions

We offer a broad range of polypropylene (PP) and polyethylene (PE) bags for a multitude of industrial and retail applications. From batch inclusion valve bags, PP woven bags to roll stock FFS film, Southern Packaging provides high performance flexible plastic packaging tailored to meet the demands of our customers.

PP and Polyethylene Packaging Applications

Polypropylene and polyethylene packaging is the high strength, cost-effective alternative to traditional multi-wall paper bags. Made from lightweight, moisture-resistant materials, polypropylene bags are quickly becoming the preferred packaging product for the aggregate, agricultural, food, and feed industries.

Product Features

- Economical Packaging Costs

- Superior Graphics and Printing Capabilities

- Grease and Moisture Resistant

- High Burst Strength and Puncture Resistant

- Sustainable and Recyclable Poly Films

Product Applications

Polypropylene and polyethylene packaging is the high strength, cost-effective alternative to traditional multi-wall paper bags. Made from lightweight, moisture-resistant materials, polypropylene bags are quickly becoming the preferred packaging product for the aggregate, agricultural, food, and feed industries.

Building Products

%201.svg)

Carbon Black

.svg)

Chemicals

.svg)

Food Products &

Ingredients

Industrial Sand

Minerals

Pet Food

Petrochemicals &

Resins

Pigment

Road Patch & Repair

Plastic Valve Bags

A common industrial packaging option designed to package a wide variety of dry flowable products on spout packing equipment. Plastic valve bags are designed to perform on most existing paper valve bag packing machinery.

Polyethylene Block Bottom Valve Bag

- Manufactured from virgin PE resin

- Suitable for granular or fine powders

- Available in low melt film for batch inclusion applications

- 4.0 - 7.0 mil film thickness

- Custom film colors for easy product identification

- Micro-perforated, breathable fabric

- 1-8 color print

- Available in sonic seal, tuck-in, or standard internal sleeve

- Sift resistant construction

- Labeling and Lot # printing compatible

- Anti-skid embossing / sanded finish

- 100% recyclable

- 60 day lead time on custom orders

- UN Certification available

Batch Inclusion Polyethylene Block Bottom Valve Bag

- Manufactured from virgin low melt PE resin

- Ideal for chemicals utilized in the paint, rubber, and tire manufacturing process including Carbon Black and Titanium Dioxide

- Package melts and product disperses uniformly into mixture

- Custom formulated film for desired melt point 100C – 108C

- Ensures consistent batch quality

- Eliminates product loss & contamination

- Minimizes worker exposure to hazardous materials

-1.png?width=553&height=520&name=Rectangle%2022%20(2)-1.png)

Woven Polypropylene Block Bottom Valve Bag

- Manufactured from woven polypropylene tapes and polypropylene film

- Suitable for granular or fine powders

- High burst strength – eliminates breakage and reduces product loss

- Custom woven fabric colors

- Micro-perforated, breathable fabric

- Printable up to 8 colors, including Photorealistic graphics

- Available in sonic seal, tuck-in, or standard internal sleeve

- Moisture resistant for outside storage

- Excellent stackability

- 1,600 hour UVI rated

- Auto-bagger, Auto-palletizer compatible

- Labeling and Lot # printing compatible

- Anti-skid embossing

- 100% recyclable

- Unprinted bags IN STOCK for immediate shipment

- 120 day lead time on custom orders

Valve Types

Standard Internal Valve

A strip of poly pasted into the valve opening to make the valve stronger and more sift-resistant. In general, this is the most economical valve type.

Tuck-In Sleeve

An outer sleeve extension that is folded and tucked in by hand after thebag has been filled. A thumb notch may be included for easier presentation on the packing equipment.

Sonic Seal Sleeve

An outer poly sleeve extension that is suitable for ultrasonic hermetic sealing. Sleeve material can be PE or Spunbond PP.

Open Mouth Poly Bag Types

Click to navigate to a bag type:

BOPP Bag

Biaxially Oriented Polypropylene or BOPP is a flexible material derived from melting and biaxially orienting (stretching on both axis) a polypropylene polymer. The process of biaxially orienting polypropylene, stretching it in the machine direction and transverse direction, improves the films physical properties, such as water vapor barrier, stiffness, dimensional stability, and optics.

Technical Applications & Features

- SOM and PBOM constructions

- Tubular & Back Seam Design

- Photographic print quality

- Matte and glossy finishes

- 5 x 5 and 10 x 10 weave

- Clear and printed gussets

- High Tensile Strength

- Puncture, tear, & scratch resistant

- Moisture resistant

- Grease & odor protection

- Available with easy-open feature

- 100% recyclable polypropylene

Woven Polypropylene / Paper Laminate Bag

Often referred to as a Paper-Poly bag, this bag style offers superior functionality over traditional multi-wall paper bags. The woven polypropylene and paper mix is ideal for feed, fertilizer, pet food, and seed.

Technical Applications & Features

- Manufactured via extensible paper and woven polypropylene lamination

- SOM construction

- Back seam design

- Compatible with automated bagging equipment

- Up to 6 color flexographic printing

- Brown kraft or bleached white outer layer

- Puncture & tear resistant

- Moisture resistant

- Grease & odor protection

- Available with easy-open feature

- Anti-skid feature

Rollstock & FFS Bag (Form, Fill, & Seal)

Designed for high speed filling efficiency, Rollstock and FFS film bags are an advanced packaging style used on automated equipment. The packaging material is fed off a roll and formed into the proper shape for the product. FFS films are common in the building materials, petrochemicals, and consumer packaged goods markets.

Technical Applications & Features

- Format options include Vertical FFS, Horizontal FFS, and tubed rollstock (gussetted & non-gusseted)

- Made from 100% virgin Polyethylene

- Up to 10 color printing

- Embossing for Anti-Skid

- Nano-Perforation for air release

- Lacquer finishes for high gloss graphics

- Custom Coefficient of Friction for anti-slip

- 5 Layer Coextrusion for complex barriers

- Metalized films available

-1.png?width=437&height=520&name=Rectangle%2019%20(7)-1.png)

Woven Polypropylene Open Mouth Bags / Sand Bags

- Manufactured from 100% Virgin Polypropylene

- Suitable for granular products including feed, seed, and sand

- Laminated and Unlaminated Woven Polypropylene Fabric

- High burst strength – eliminates breakage and reduces product loss

- Custom woven fabric colors

- Micro-perforated, breathable fabric

- Printable up to 4 colors

- Moisture resistant for outside storage

- Available with pre-installed ties

- 1,600 hour UVI rated

- Auto-bagger, Auto-palletizer compatible

- Labeling and Lot # printing compatible

- Anti-skid embossing

- 100% Recyclable

.png?width=735&height=802&name=UNBag%20(2).png)

Industry Applications for Polypropylene Bags

Southern Packaging has serves hundreds of clients from various industries. Our comprehensive line of polypropylene bags are trusted by businesses in fields like:

Agriculture

Our woven polypropylene bags are commonly used in the agriculture sector for packaging and transporting feed, grains, and other agricultural commodities.

Mining and Minerals

Woven bags are commonly used in the mining and minerals industry to efficiently transport and store various materials, such as aggregates, ores, and minerals.

Food and Beverage

Food grade bulk bags and woven propylene bags are excellent packaging solutions for the food and beverage industry. They are trustworthy options for storing and transporting bulk food items.

Animal Feed

Our premium polypropylene feed bags offer exceptional quality and value in the animal feed industry, providing durable and reliable packaging solutions for a wide range of feed products.

Hazardous Waste

Strong and durable bags are often the preferred choice for hazardous waste storage and disposal in various industries.

Open Mouth Bag Constructions

Click to navigate to a bag type:

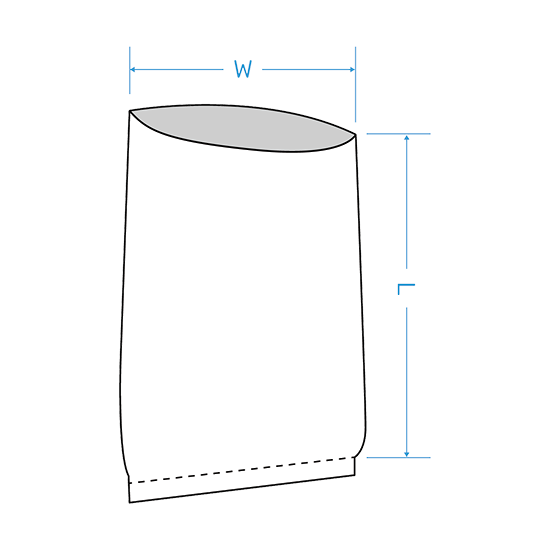

Sideweld / Side-Seal

- General purpose, low cost bag

- Light to medium duty

- Made from folded polyethylene sheeting, sealed on each side

- Bag opening can have a lip or backflip

- No seam on bag bottom

- Bag can have a bottom gusset

- Bag handle, punches, holes, hang holes, and thumb notches are easily applied

- Measured W x H

- Registered or random repeat print

- Available on a roll or flat packed

- Metalized films available

- FDA Approved materials

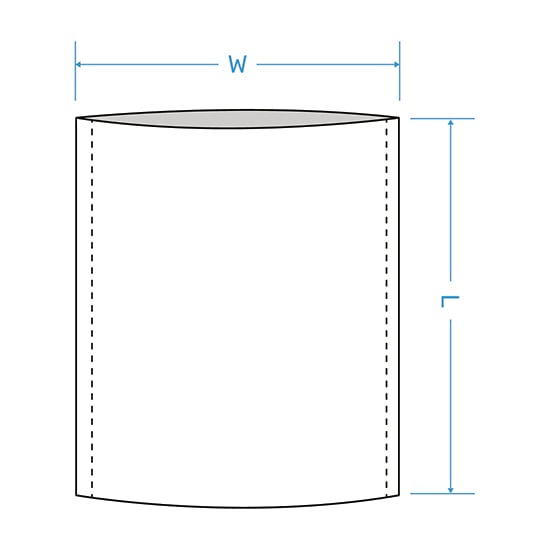

Flat Tube / Tubular Bottom Seal

- General purpose bag

- Medium to Heavy duty

- Ideal for food, pharmaceuticals, mulch, and hazardous waste

- Made from tubular film sealed at the bottom

- No seams on bag sides

- Recommended for watertight and airtight bag seals

- Bag handle, punches and holes can be applied

- Measured W x H

- Registered or random repeat print

- Available on a roll or flat packed

- FDA Approved materials

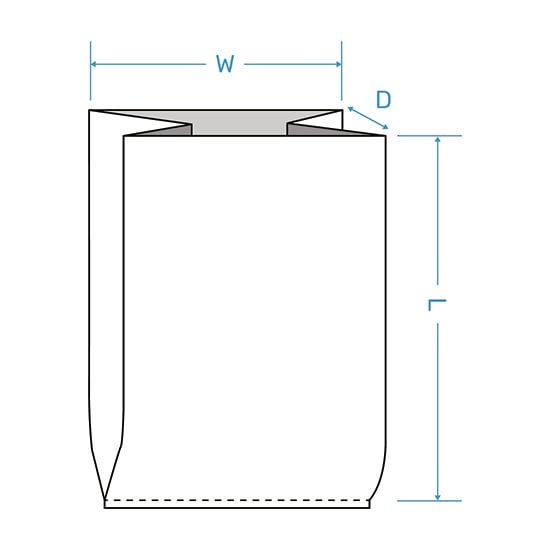

Gusseted

- High end plastic package

- Gussets are the expandable side (or bottom) portion of an open mouth bag which allows for volume

- Gusseted bags are available with side gusset or bottom gusset

- Gusset sides contour to a box shape

- Excellent stability and stackability

- Bag handle, punches and holes can be applied

- Line or Process Print

- Measured W x H X G

- Ideal for stand-up pouches or retail packaging

- Available on a roll or flat packed

- Meets FDA and USDA specification

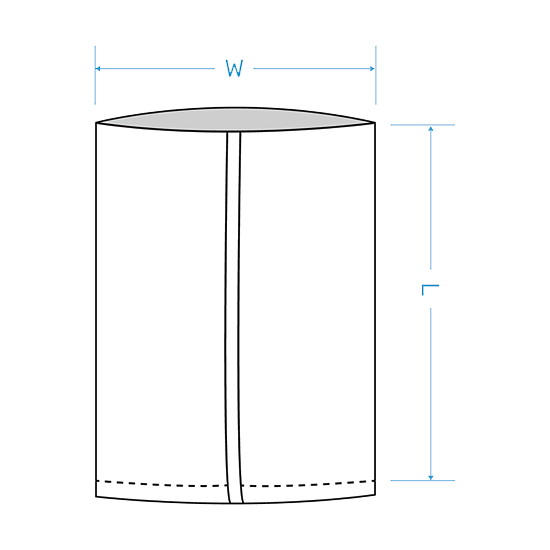

Back Seam

- Made from folded polyethylene sheeting, sealed on the back to form a tube with an overlap seal

- Back seam style offers consistent sizing for improved performance on automated packaging equipment

- Can be gusseted or non-gusseted

Get In Touch

Our team can deliver the packaging you need, when you need it. Complete your info here and we'll be in touch quickly.