Why CROHMIQ™ Type D Anti-Static Bulk Bags Offer the Best Static Protection

When handling dangerous bulk powders, or filling and discharging FIBCs where explosive gases or vapors are present, static protection is essential to..

October 6, 2020

When handling sensitive bulk powders, or filling and discharging where flammable gases or vapors are present, static protection is essential to prevent a fire or catastrophic explosion. Utilizing anti-static FIBCs in the form of either a Type C or Type D bulk bag can offer you protection against electrostatic discharges.

Continue reading as we discuss how anti-static bulk bags work and break down the different classifications associated with FIBCs.

Static electricity is created by an imbalance of electric charge within or on the surface of a material. The charge remains until it is able to move away by means of an electric current or electrical discharge. An electrical discharge is commonly represented in the form of a spark.

When bulk bags are filled and discharged, the movement of the material across the bag’s fabric can cause a buildup of static electricity. Electrical sparks can create severe hazards in those industries dealing with flammable substances, where a spark might ignite explosive mixtures. Airborne vapors and dust clouds of finely powdered substances can become combustible or explosive. Every year manufacturing facilities and warehouses across the globe explode or catch fire due to the ignition of their products or raw materials.

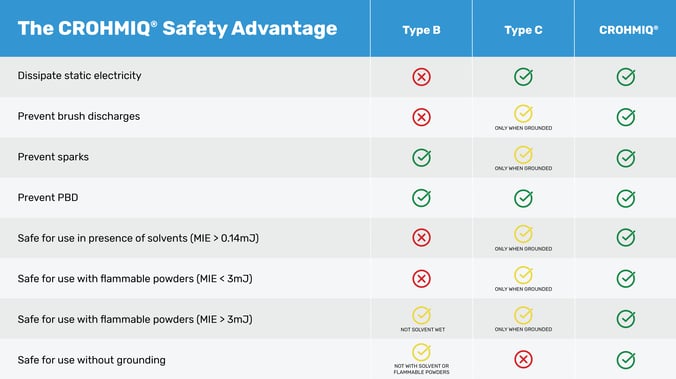

Anti-Static Bags are engineered to control static electricity thereby significantly reducing the risk of a fire or explosion. The following information is intended to explain the differences between the 4 bulk bag classifications or “types”: A, B, C, and D.

Type A bags are made of standard woven non-conductive fabric and does NOT provide ANY protection against static electricity.

Type A bags are safe for transporting NON-FLAMMABLE products. Flammable materials or gases MAY NOT be present outside of the bag.

Bag made of standard woven non-conductive fabric (including the lining which is usually applied) with low breakdown voltage designed to prevent sparks and propagating brush discharges.

Type B bags are safe for transporting FLAMMABLE products. Flammable materials or gases MAY NOT be present outside of the bag.

Type B bags differ from Type A bags in that the breakdown voltage through the fabric, including the lining, shall be low enough to prevent electrostatic discharges, such as propagating brush discharges (< 4kV). Spark discharges may occur from the surface of FIBC Type B if they become contaminated by, or coated with, a conductive material (water, grease or oil, for example). Precautions must be taken to avoid such contamination and to avoid conductive objects such as tools or metal clamps being placed on the FIBC.

Although Type B bulk bags can prevent propagating brush discharges, they are NOT considered anti-static bulk bags because they do not dispel an electrostatic charge.

.jpg?width=300&name=image1%20(1).jpg) Type C

Type C Bag made of woven conductive fabric or from a non-conductive fabric with interconnected conductive threads or filaments. Type C bags are designed to control electrostatic charges by grounding. They are safe for transporting FLAMMABLE products. Flammable materials or gases MAY be present outside of the bag. However, Type C FIBC bags MUST BE GROUNDED during filling and discharge.

The pattern of the conductive threads or filaments is either:

Type C bulk bags must be equipped with a grounding connection to which all conductive panels, threads or filaments are electrically bonded. The resistance of the grounding point from anywhere on the conductive fabric and from the conductive threads and filaments must be less than 108 Ω.

The lift loops of FIBC Type C bag must also contain conductive threads or filaments with a resistance to the grounding point of less than 108 Ω.

The bag must also meet the requirements relating to the breakdown voltage of FIBC Type B (<4kV).

In order to avoid “spark” discharges, it is essential that the bag is always securely grounded. A label must be attached to the FIBC bags stating the position of the grounding points and clearly outlining the grounding requirements during filling-in or emptying operations. The phrase, “FIBC must be grounded prior to opening” must be printed in big bold letters on two sides of each bag.

.png?width=229&height=303&name=image3%20(1).png) Type D

Type DBag made of woven fabric which enables electrostatic charge to be dissipated without being grounded. The fabric of a Type D FIBC generally contains conductive threads or filaments which safely dissipate the charge through low energy "corona" discharges. Some Type D bags have a low resistivity lining, which can reduce the risk of incendiary discharges. Type D bulk bags are safe for transporting FLAMMABLE products. Flammable materials or gases MAY be present outside of the bag.

Type D FIBCs are NOT REQUIRED TO BE GROUNDED during filling and discharge.

Type D FIBCs must meet the requirements relating to the breakdown voltage of the FIBC Type B (< 4 kV).

Ungrounded conductors, such as metal drums or persons in the vicinity of a Type D bag, can become charged. It is imperative to ensure that all conductors are grounded in the presence of explosive atmospheres.

“Spark” discharges may occur from the surface of the FIBC Type D if it is contaminated by, or coated with, a conductive material (water, grease or oil, for example). Precautions must be taken to avoid such contamination and to avoid conductive objects such as tools or metal clamps being placed on the FIBC.

Type D bulk bags such as Crohmiq™ bulk bags are manufactured with fabric containing quasi-conductive yarns that safely dissipate static electricity into the atmosphere via safe, low-energy corona discharge.

At Southern Packaging, LP, we are the largest U.S. on-demand provider for FIBCs. Contact us today to discuss our available stock or discuss our inventory management and warehousing options available for your business.