Rounded Corner Slip Sheets and Layer Pads for Consumer Packaged Goods

What is a slip sheet?

June 21, 2023

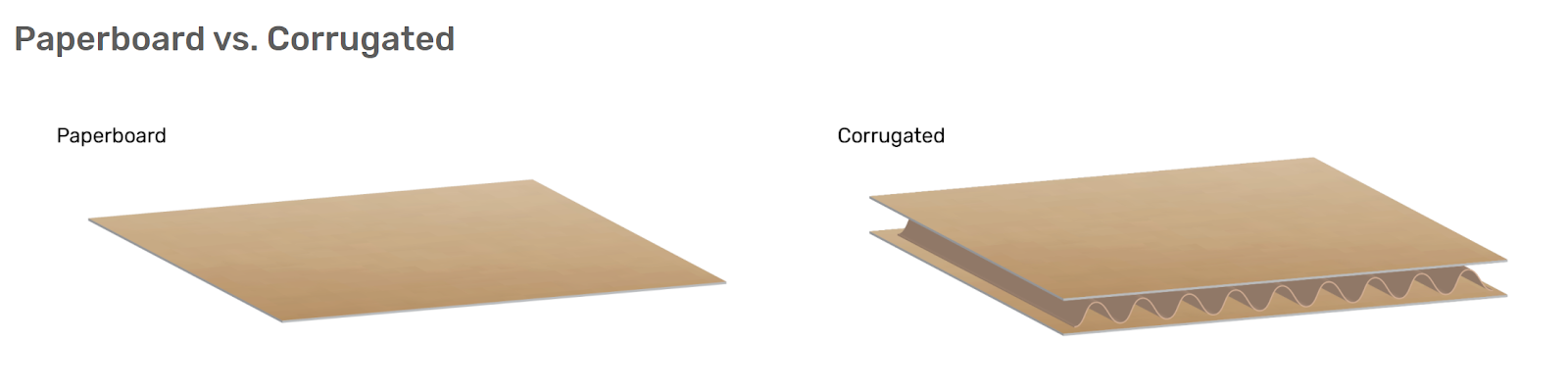

A slip sheet is a thin sheet of heavy-duty paperboard, corrugated fiberboard, or plastic used as a load support device for shipping palletized material.

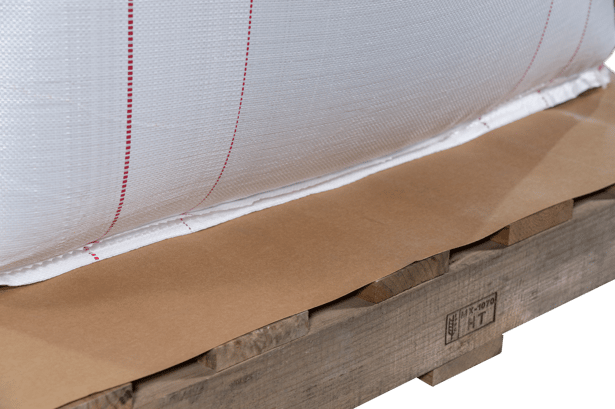

Slip sheets are typically placed between a wooden pallet and the palletized material to prevent palletized products from incurring damage during storage, handling, and shipping.

Slip sheets defend bagged and boxed materials against punctures and tears caused by pallet nails and deck boards. They also serve as a moisture-resistant barrier between the ground and your product, preventing mold and mildew.

Weighing as little as one pound, high-strength paperboard sheets are strong enough to support loads up to 4,000 pounds.

We recommend using slip sheets for all flexible intermediate bulk container (FIBC), multi-wall paper, and poly bag shipments.

For many years corrugated fiberboard was the material of choice for slip sheet converters and their customers. However, corrugated has become increasingly expensive, challenging to ship economically, and difficult to store in large quantities.

The availability of high-strength, inexpensive paperboard has rendered the corrugated sheet nearly obsolete.

Southern Packaging is proud to offer a new alternative to traditional corrugated slip sheeting that is guaranteed to save your company money, space, and time.

REQUEST A QUOTE.jpg?width=480&height=320&name=Why%20Use%20Slip%20Sheets%20for%20Pallets%20%20(1).jpg)

The advantages of paperboard over corrugated are clear. Transitioning from corrugated to single-face paperboard saves you money, space, and time.

In general, paperboard slip sheets are 30% less expensive than traditional corrugated. Transportation and shipping costs per sheet are also significantly improved due to the density of the pallet unit.

A standard pallet unit of corrugated sheets only contains 300 pieces, whereas a pallet unit of paperboard contains 2,000 sheets.

In other words, you can expect to get nearly seven times the number of sheets on a pallet when compared to corrugated. A full truckload of paperboard sheets will contain up to 40,000 pieces.

Many of our customers utilize automated equipment for placing a sheet on a pallet. Increasing the number of sheets per pallet allows operators to spend less time replacing sheets in the sheet-placing machine.

Paperboard comes in a variety of types. Each type is made from several layers of solid kraft paper pressed together under high heat and pressure. Common types include:

Each board type contains recycled material. Sheets can be clay coated for additional moisture resistance.

The cost of a slip sheet depends on several factors including board type, thickness, and size. Prices for the most common sizes and styles range from $.40 to $.75 each. A pallet generally consists of 2,000 sheets.

Southern Packaging stocks a substantial supply of on-demand slip sheets in a wide variety of sizes and styles.

Contact a member of our experienced sales team today to discuss your unique packaging needs and discover how we can help you achieve your goals. Our team of experts is ready to assist you.

Contact Us