Eliminate FIBC Supply Chain Uncertainty With Vendor Managed Inventory

How will the global viral pandemic affect the FIBC industry in 2021? Eliminate supply chain uncertainty with a Vendor Managed Inventory (VMI) program

February 4, 2021

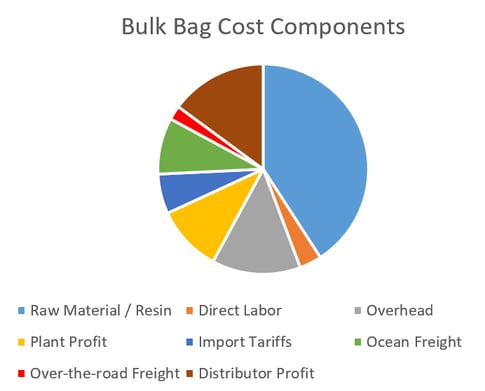

We are often asked by our customers to explain the wide variability in pricing from one bag to the next. Unfortunately, there is no one-size-fits-all answer.

The following cost information is intended to assist purchasers in identifying, comparing, and choosing an FIBC that offers the desired level of value. Continue reading as we break down key industry terms in order to simplify your bulk bag purchasing process.

The largest cost component of a bulk bag is resin. Raw materials including fabric, webbing, and sewing thread are derivatives of petroleum-based resins. Consequently, the price of raw materials fluctuates in accordance with oil and gas prices.

Bag production is a labor-intensive process requiring a high level of skill and experience. While resin extrusion and fabric weaving are fully automated, bag stitching remains a manual process. In a typical production line, 10-20 workers will handle cutting, stitching, quality control, and packing. Large plants can employ hundreds to thousands of workers.

Labor rates vary greatly from country to country. The competitive labor advantage has driven the bulk of bag production overseas to India, China, and Turkey.

(Lowest) India < China < Turkey < Mexico < U.S.A (Highest)

Disproportionately low wages allow the direct labor cost component of a bulk bag to remain marginal.

Overhead manufacturing costs can include equipment, buildings, utilities, and factory management salaries. Indirect costs to convert raw materials including extrusion, weaving, and sewing machines are dependent on the current cost of natural gas and electricity.

Not all plants are created equal. For example, state-of-the-art production facilities with SQF rated cleanliness standards may incur significantly higher overhead costs than basic industrial bag facilities.

Understanding the quality and production capabilities of the plants that produce your bag is critical when sourcing the right bag for your business.

The money remaining after all manufacturing and administrative costs are incurred.

FIBCs are subject to import tariffs (under HTS Code 6305.32.0010) when imported from certain overseas countries. In general, the import tariff on bulk bags is equal to 8.4% of the commercial value of the bags. Additional surcharges and fees apply, bringing the average total tariff to approximately 9%.

Recently, additional tariffs were imposed on Chinese manufactured FIBCs. This raised the total tariff to over 23.4%. Trade relations between China and the United States continue to evolve and duties will likely be reduced at some point in the future. Nevertheless, tariffs are a material cost component of an imported bag.

The value of the dollar vs. foreign currencies can impact the cost of an imported bag. Strong dollar = cheaper overseas bulk bags.

Imported bulk bags are shipped from the manufacturing plant to the United States in 20’ and 40’ sea containers. Ocean freight is a significant cost component of a bulk bag. Freight from India and China to the United States can range from $3,000-$5,000 per container.

Imported bulk bags are handled by freight and customs brokers to gain entry into the United States. Charges for these services generally is generally nominal.

Once the sea container arrives to the U.S. port, it must be transported over the road to the distributor or end-user’s location. Major ports of entry include Houston, Long Beach, New Orleans, and Savannah. Oftentimes, the container may be shipped via rail to the nearest customer rail ramp, then offloaded and delivered via truck.

Oftentimes, customers elect to leverage a distributor’s warehouse to store bags for an extended period. This eliminates the typical 12-16 week lead time for normal bag production.

Distributors factor expenses such as rent, utilities, forklifts, taxes, and personnel wages into the warehousing cost component of the bag price. Warehousing costs typically add 4-8% to the price of a bag.

Profit margins are determined by the volume of product needed, the difficulty in manufacturing the required product, and the customer’s creditworthiness.

There are 14 major parameters of a bulk bag that determine the overall cost.

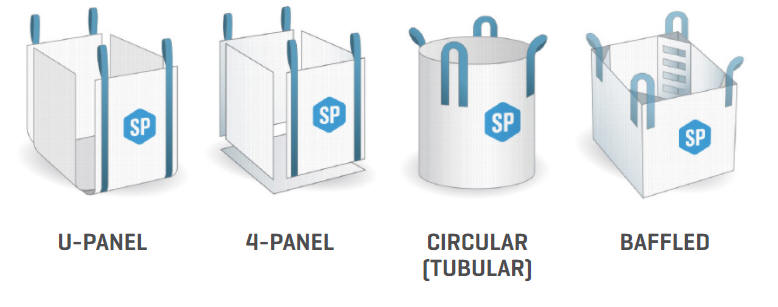

There are 4 main bag types that play a role in the overall bulk bag cost. When selecting a bag type Circular is the cheapest option followed by U-Panel, 4-Panel, and Baffled in that order. The graph below showcases the different bag types.

Bag size is a more obvious cost factor. The bigger the bag, the bigger the cost. Smaller bags will be cheaper due to the amount of material being spared.

Another FIBC cost factor is fabric weight. The heavier the fabric used the more expensive the bulk bag can be. Heavier fabrics are recommended for different products, contact our sales team to help determine which fabric weight is right for you and your business.

Type A < Type B < Type C < Type D

Uncoated < Coated

Safe Working Load is a function of fabric weight. As SWL increases the fabric weight required to support the load must increase resulting in a more expensive bag.

5:1 SF < 6:1 SF

Open top < Spout Top < Duffle Top

For spout tops, price is determined based on the size of the spout requested.

We went into detail about the different bulk bag cost components and drivers, now what? Connect with our team of bulk bag specialists to start the conversation today!