Type C vs. Type D Anti-Static Bulk Bags: Which Do You Need?

Static control is a critical safety requirement when handling flammable powders, chemicals, and combustible dusts. During filling and discharge, bulk..

July 10, 2023

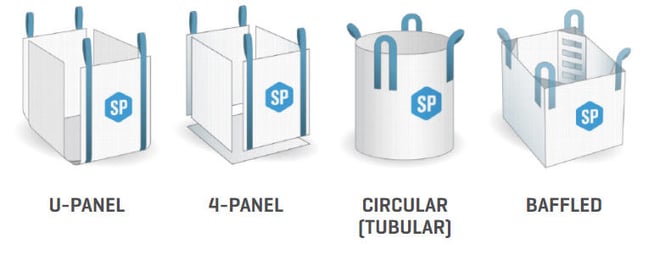

A flexible intermediate bulk container (FIBC) is an industrial container made of a flexible fabric designed for storing and transporting dry, flowable products. These large, sturdy bags offer numerous benefits in terms of storage, transportation, and handling of bulk materials.

However, it is crucial to understand that not all FIBC products are created equal. Different types of FIBCs exist, each designed to meet specific requirements and address unique challenges.

Keep reading to learn the differences between the five types of FIBC bags and which type may be best suited to your bulk packaging needs.

.png?width=480&height=320&name=UPanelBulkBagHighlight-SouthernPackaging%20(1).png) U-panel bags are constructed with three main body components: one piece that runs the full length of the bag forming the bottom and two sides (the “U”) and two additional pieces of fabric sewn between the “U” on two sides (the “panels”).

U-panel bags are constructed with three main body components: one piece that runs the full length of the bag forming the bottom and two sides (the “U”) and two additional pieces of fabric sewn between the “U” on two sides (the “panels”).

Generally, U-panel bags will maintain a square shape when filled, especially with the addition of internal baffles. U-panel bags are an industry standard and the most popular type of construction.

.png?width=480&height=320&name=CircularBulkBagHighlight-SouthernPackaging%20(1).png) Circular bags, also called tubular bags, are constructed with two main body components: the body tube and the base.

Circular bags, also called tubular bags, are constructed with two main body components: the body tube and the base.

The body tube is made with seamless tubular fabric that forms all sides of the bag, allowing for stitching only at the top and base of the bag. Although the fabric is tubular, when filled, a circular bag will still somewhat resemble a square bag.

There is a common misconception about circular bags regarding their shape when filled. They are not truly circular — they are simply constructed with a single piece of fabric that forms all four sides of the bag. While they still resemble square or rectangular FIBCs when filled, they will hold that shape the least out of all the construction types.

.png?width=480&height=320&name=4PanelBulkBagHighlight-SouthernPackaging%20(1).png) A very common bulk bag style, 4-panel bags are constructed with five main body components: four side panels and the base.

A very common bulk bag style, 4-panel bags are constructed with five main body components: four side panels and the base.

When filled, a 4-panel bag will hold its square shape similar to other construction types. Typically, 4-panel bags will hold their shape better than U-panel bags, while U-panel bags will hold their shape better than circular bags.

Due to the large amount of stitching required, a 4-panel bag has a greater opportunity to fail at the seams and is prone to sifting. Nevertheless, 4-panel bags are ideal for storage due to the way they hold their shape when filled.

.png?width=480&height=320&name=BaffledBulkBagHighlight-SouthernPackaging%20(1).png) Baffles are an internal component that can be added to a U-panel, 4-panel, or circular-style bag. More specifically, baffles are fabric panels or strings sewn inside each of a bulk bag’s four corners that allow it to maintain a square shape when filled.

Baffles are an internal component that can be added to a U-panel, 4-panel, or circular-style bag. More specifically, baffles are fabric panels or strings sewn inside each of a bulk bag’s four corners that allow it to maintain a square shape when filled.

Without baffles, the construction types listed above can bulge or belly at the sides when filled.

Also called Q bags, baffled bags are ideal due to their stability and stackability. They also improve overall storage capacity. The most common type of baffled bag is a 4-panel baffled bag.

.png?width=480&height=320&name=Single%26DblBulkBagHighlight-SouthernPackaging%20(1).png) Produced from single tubular fabric, single and double-loop bags are widely accepted as being more cost-effective than traditional four-loop bags.

Produced from single tubular fabric, single and double-loop bags are widely accepted as being more cost-effective than traditional four-loop bags.

The body fabric of the bag itself is extended into a lifting loop which gives the bag a higher breaking strength and makes the FIBC easier to lift. The loops can be wrapped with colored sleeves to assist in easily identifying the bag.

An inner liner is usually incorporated inside the bag to keep the packed product free from moisture and other contaminants.

In addition to the construction styles discussed above, there are other characteristics of flexible container bags that impact their function and application.

One such characteristic is top style. Determining the appropriate top style for your bulk bag depends on various factors, including the nature of your material, the handling process, and your specific requirements. The different FIBC top styles are:

Understanding these differences can contribute to more efficient and effective material handling processes.

When determining whether to use a coated or uncoated bulk bag, several considerations come into play.

First, assess your product's characteristics and specific requirements. If your material is moisture-sensitive or prone to leakage, a coated bulk bag offers added protection against contamination. Additionally, if your product generates significant dust, a coated bag can effectively contain particles.

Compatibility with handling equipment and compliance with industry regulations should also be evaluated.

.png?width=480&height=320&name=LiftLoopsHighlight-SouthernPackaging%20(1).png) Lift loops are a standard feature found on the majority of bulk bags. Typically constructed from a durable woven poly material, lift loops possess high tensile strength to withstand the weight and demands of lifting and transporting FIBC packaging.

Lift loops are a standard feature found on the majority of bulk bags. Typically constructed from a durable woven poly material, lift loops possess high tensile strength to withstand the weight and demands of lifting and transporting FIBC packaging.

The two main types of lift loops are cross corner and corner seam. Cross corner lift loops are commonly utilized in circular bulk bag constructions. They’re sewn onto the main body of the FIBC and create an arched structure that extends over each corner.

Corner seam lift loops are typically found in U-panel and 4-panel bulk bag constructions. These lift loops are sewn along the side seams of the bag, starting and ending at the same point, which creates a teardrop shape.

The bulk bag classifications below refer to different levels of protection against electrostatic discharge (ESD) risks:

FIBC stands for Flexible Intermediate Bulk Container. It's a type of industrial container made from flexible fabric designed for storing and transporting dry, flowable products.

An FIBC is an industrial strength bag. It offers flexibility, sturdiness and numerous benefits in terms of storage, transportation, and handling of bulk materials. In addition, they come in different styles and types including U-panel, Circular, 4-panel, Baffled, and Single Loop and Double Loop bags, each designed to meet specific requirements and address unique challenges.

When it comes to bulk material handling, understanding the various types of FIBC packaging is critical.

Southern Packaging, LP stocks the largest inventory of on-demand FIBCs in the country. We can help you choose the right bulk bag type for your business, ensuring that your packaging solutions align with your specific requirements and industry regulations.

For more information about our FIBC stock or to request a quote, contact a member of our team today.